$2,500 / year

Earn certification & 58 hours of ACPE-accredited CE

Group Purchases

Request more information about our enterprise solutions and clinical resources from TRC Healthcare.

Program Overview

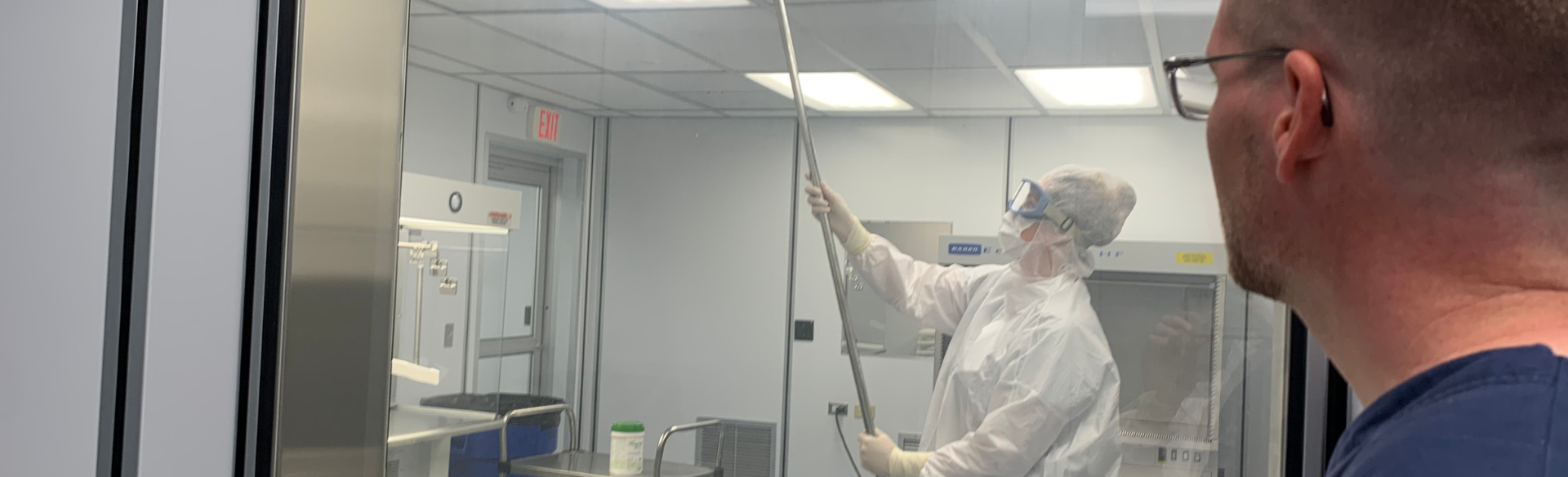

This training program delivers best-in-class, comprehensive sterile compounding education to state board pharmacy inspectors to drive pharmacy excellence and deepen sterile compounding expertise.

Participants can complete content at their own pace over 12 months from the date of purchase. This includes the option to choose when they attend their required live webinar session.

Participants will have the option to select between the following 2024 dates to attend the live webinars and earn 5 hours of live credit from this virtual training:

Facility Design & Certification (2 hrs) – all 11a-1p PT

- Friday, May 3, 2024

- Thursday, May 23, 2024

- Wednesday, June 19, 2024

- Tuesday, July 9, 2024

- Wednesday, August 21, 2024

- Friday, September 20, 2024

- Thursday, October 10, 2024

- Wednesday, November 6, 2024

- Tuesday, December 3, 2024

Best Work Practices & Identifying Insanitary Conditions (3hrs) -11a-2p PT

- Monday, April 29, 2024

- Friday, May 17, 2024

- Thursday, June 20, 2024

- Wednesday, July 10, 2024

- Tuesday, August 27, 2024

- Monday, September 16, 2024

- Friday, October 11, 2024

- Thursday, November 7, 2024

- Wednesday, December 4, 2024

Participants will earn up to 58 hours of ACPE-accredited CE, including the 5 live credits, 20 hours of on-demand webinars, and 33 hours of interactive CE. Content includes lively discussions as well as practical learning exercises that simulate real-life work scenarios.

If you have already completed your inspector training within the last 2 years and need to maintain your certification, sign up for our 23-hour Sterile Compounding Inspector Refresher Training. Learn more here.

This training is only open to Board of Pharmacy inspectors and regulatory agencies.

Course Curriculum

Overview of Environmental Monitoring (1 hr ACPE credit)

Learn about essential components of an environmental monitoring program, including processes for viable air and surface sampling.

Viable Air and Surface Sampling (1 hr ACPE credit)

Review viable air and surface sampling and the correct sequence for these as part of an overall engineering monitoring program.

Investigation and Remediation of Viable Environmental Monitoring and Personnel Sampling Excursions (2 hr ACPE credit)

Learn about common microorganisms in sterile compounding environments and how to investigate, document, and remediate a microbial excursion.

Hand Hygiene and Garbing for Sterile Compounding (1 hr ACPE credit)

Review requirements for hand hygiene and the use of garbs when performing sterile compounding.

Best Practices for USP 797 Material Handling (1 hr ACPE credit)

Learn about proper material handling and its role in reducing the bioburden introduced into the primary and secondary engineering controls (PECs and SECs).

Aseptic Technique and Conduct for Sterile Compounding (1 hr ACPE credit)

Review the concept of performing aseptic compounding in a disciplined and consistent fashion to safeguard patients from preventable disease and injury related to contaminated compounded sterile preparations.

Hazardous Drug Overview (1 hr ACPE credit)

Learn about health and occupational risks of exposure to hazardous drugs and strategies to implement for safe handling of hazardous drugs.

Containment Primary and Secondary Engineering Controls (USP 795 and 797) (1 hr ACPE credit)

Learn how containment engineering controls operate and function to protect you from hazardous drugs and their potentially damaging effects.

Personal Protective Equipment for HD Handling for USP 795 and 797 Compounding (1 hr ACPE credit)

Review the more complex garbing required for handling and compounding hazardous drugs.

HD Work Practice: Receiving through Transport to Patients (1 hr ACPE credit)

Review required and best practices for handling hazardous drugs, including containment of residue, packaging, and transporting compounded preparations.

HD Work Practice: Decontamination and Spill Management (USP 795 and 797) (1 hr ACPE credit)

Learn about decontamination in hazardous drug handling environments, managing spills and disposing of hazardous drugs, and documentation requirements.

History of Sterile Compounding (1 hr ACPE credit)

Learn about the evolution of pharmacy compounding and the development of national standards of practice.

Determining USP 797 Beyond-Use Dating (1 hr ACPE credit)

Review USP requirements around beyond-use dating (BUD) and recognize the risk of microbiological contamination in compounded sterile products.

Quality Releases and Final Checks for Sterile Compounding (1 hr ACPE credit)

Learn about the requirements set out by USP 797 for release inspections and testing, including visual inspection, sterility testing, and bacterial endotoxins testing.

USP 797 CSP Handling: Staging through Transport (1 hr ACPE credit)

Consider unique factors when advancing a CSP from staging to transport, including numerous opportunities where mistakes can be made, and how robust procedures can help prevent errors.

Master Formulation and Compounding Records for Sterile Compounding (1 hr ACPE credit)

Use compounding documentation to provide evidence of procedures or activities performed during compounding, such as compounding instructions, equipment required, and calculations.

Standard Operating Procedures for Sterile Compounding (1 hr ACPE credit)

Recognize the importance of standard operating procedures (SOPs) to ensure the preparation of medication is reproducible and reduce preventable errors and patient injuries.

General Elements of Documentation for Sterile Compounding (1 hr ACPE credit)

Review key elements of good documentation, including USP 797 requirements, and why it’s important to maintain good documentation at your compounding facility.

Use of Equipment and Integrating Technology for Sterile Compounding (1 hr ACPE credit)

Recognize how to utilize automated compounding devices (ACDs) for sterile compounding and the techniques and work practices that must be implemented to minimize microbiological contamination of compounded sterile preparations.

USP 797 Primary Engineering Controls (1 hr ACP credit)

Review primary engineering control requirements, including placement, use, and certification requirements.

USP 797 Secondary Engineering Controls (1 hr ACPE credit)

Review regulations related to secondary engineering controls and fundamentals of cleanroom requirements for sterile compounding.

Personnel Competency Testing in Aseptic Manipulation (1 hr ACPE credit)

Learn about desired aseptic technique for media-fill tests and documentation, plus resources used for training and how these relate to organizational standard operating procedures.

Sterile Compounding Environments Principles of Cleaning and Disinfection (1 hr ACPE credit)

Learn about cleaning requirements, including proper selection, preparation, and use of cleaning agents and supplies.

Cleaning of Primary Engineering Controls for Sterile Compounding (1 hr ACPE credit)

Recognize differences in cleaning agents and frequency based on the types of compounded preparations and primary engineering controls.

Cleaning of Secondary Engineering Controls for Sterile Compounding (1 hr ACPE credit)

Review daily and monthly cleaning activities for a sterile compounding facility and explain the rational for these.

Quality Management of Sterile Compounding (1 hr ACPE credit)

Acquire a better understanding of quality assurance (QA) expectations relative to your role and the importance of an integrated quality management system (QMS) that works to prevent errors from recurring.

Use of Supplies and Components (1 hr ACPE credit)

Review common supplies (syringe, needle, filter, etc) used in sterile compounding, how to select the appropriate syringe size, and the processes for handling these items.

Best Practices for Mixing Outside of ISO-Classified Conditions (USP 797) (1 hr ACPE credit)

Take away information on how best to ensure patient safety when you mix sterile drugs outside of sterile compounding environments.

Sterility Testing Requirements of USP Chapters 71 and 797 (1 hr ACPE credit)

Learn about sterility testing, including the process and USP 71 requirements.

Bacterial Endotoxin Testing (1 hr ACPE credit)

Learn terminology and concepts related to bacterial endotoxin testing, why it’s important, and recognize sources of pyrogens.

Steam and Dry-Heat Sterilization Methods (1 hr ACPE credit)

Explore critical concepts of terminal sterilization of compounded sterile preparations and how to verify the effectiveness of terminal sterilization.

Sterilization by Filtration (1 hr ACPE credit)

Learn the limitations of sterilization by filtration, how to select the correct filter and perform filter integrity testing.

Overview of USP 800 and HD Handling for Sterile and Nonsterile Compounding (0.75 hr ACPE credit)

Draw a conclusion to the relationship between recommended practice and guidelines and how they all had an influence in the development of USP 800 and how they all apply to worker and patient safety as well as practical awareness to the potential exposure of hazardous drugs.

C-SECs for Sterile and Nonsterile Hazardous Drug Compounding (0.75 hr ACPE credit)

Learn the minimum USP chapter requirements for containment engineering controls in hazardous drug environments and determine what best practices for facility-specific designs are most appropriate for your pharmacy practice.

C-PECs for Sterile and Nonsterile Hazardous Drug Compounding (0.75 hr ACPE credit)

Distinguish the different types of C-PECs used in HD compounding settings and understand how they operate based on their individual design.

Response to HD Exposure and Spills (USP 795 and 797) (0.5 hr ACPE credit)

Learn about the critical elements of an exposure control and response plan, including elements of proper handling of hazardous medication spills.

Wipe Sampling and CSTDs for Sterile and Nonsterile Hazardous Drug Compounding (0.25 hr ACPE credit)

Explore wipe sampling and the use of closed system transfer devices in reducing the migration of hazardous medication residue out of controlled areas.

Decontamination and Cleaning in HD Environments (USP 795 and 797) (0.75 hr ACPE credit)

Examine the framework of decontamination, cleaning, and disinfection according to USP 800 and compare these steps to USP 797 requirements. Apply recommended best practices for developing effective steps to manage HD contamination at a safe level.

Sterile Compounding Contamination Control Principles (0.75 hr ACPE credit)

Achieve a practical understanding of the importance of contamination control principles and how workflow activity challenges the microbial state of control in sterile compounding environments.

Sterile-to-Sterile Compounding (1.25 hr ACPE credit)

Gain knowledge about newly required components of sterile compounding practices, including beyond-use dating, drug testing, and stability and quality release testing.

Secondary Engineering Controls for Nonhazardous Sterile Compounding (1.5 hr ACPE credit)

Learn the minimum USP chapter requirements for engineering controls and distinguish best practices for facility-specific designs that achieve operational compliance rather than just meeting regulatory compliance.

Hand Hygiene and Garbing for Sterile Compounding (1 hr ACPE credit)

Review key elements of effective hand hygiene and garbing as required by USP 797.

USP 797 Personnel Sampling (1.25 hr ACPE credit)

Examine the expanded compliance requirements now outlined in USP 797, including documentation, competency evaluation, and the development of a personnel sampling program as determined by the designated person.

Primary Engineering Controls for Nonhazardous Sterile Compounding (1 hr ACPE credit)

Receive a practical understanding of primary engineering controls (PECs), how they function by design, and how we must operate within the inherent limitations all PECs have in sterile compounding facilities.

Aseptic Work Practices Overview for Sterile Compounding (0.75 hr ACPE credit)

Learn about critical elements of aseptic work practices to use in sterile compounding.

Testing and Certification of PECs and SECs (USP 797) (1.25 hr ACPE credit)

Increase your confidence when engaging in conversations with certifiers regarding certification testing and documentation. Learn required and best practice elements of reporting to ensure quality and USP chapter compliance.

Sanitization of Sterile Compounding PECs and SECs (1.25 hr ACPE credit)

Learn more about how daily and monthly cleaning along with ongoing sanitization processes works to ensure the safety of the compounding environment.

Environmental Monitoring (1 hr ACPE credit)

Review key requirements of an environmental monitoring program and how to perform a proper investigation and remediation process in the event of an exceeded action level.

Quality Systems for Sterile Compounding (1 hr ACPE credit)

Learn more about the development and implementation of a sterile compounding quality assurance (QA) and quality control (QC) program.

Work Practice Strategies for Receiving, Storing, Compounding, and Transporting HDs and HD CSPs (1 hr ACPE credit)

Learn work practice strategies for various stages of hazardous medication handling to ensure regulatory compliance.

Donning, Doffing, and Types of Personal Protective Equipment (PPE (0.75 hr ACPE credit)

Review USP 800 requirements for donning and doffing personal protective equipment and types of PPE used in hazardous medication handling.

Nonsterile-to-Sterile Compounding (1 hr ACPE credit)

Acquire a better understanding of sterility and bacterial endotoxin testing requirements when performing nonsterile-to sterile-compounding.

Media-Fill Testing and Subsequent Gloved Fingertip Sampling (GFS) (0.5 hr ACPE credit)

Implement sound personnel sampling metrics based on chapter requirements for media-fill testing (MFT) and the additional testing elements associated with MFT evaluation.

Pharmacy Inspection Guide (1 hr ACPE credit)

Learn about crucial elements of conducting a sterile compounding pharmacy inspection to ensure a facility’s organizational state of control.

Best Work Practices & Identifying Insanitary Conditions (3 hr live, ACPE credit)

Learn about elements that make up best work practices and how to identify insanitary conditions within a sterile compounding area.

Facility Design and Certification (2 hr live, ACPE credit)

Review requirements for sterile compounding areas and learn about certifications that are needed.

Training Objectives

Build Compounding Competency. Receive a detailed education on sterile compounding, including hand hygiene and garbing, environmental sampling, and more.

Drive Pharmacy Results. Advance your understanding of USP Chapters <797> and <800> to improve quality, compliance, and patient safety.

Receive High-Quality Instruction. Strengthen your compounding knowledge while learning from true subject matter experts with 30 years of industry expertise.

Additional Training Benefits

- Improve Patient Safety. Know the latest safety, quality control, and tools to inspect compounding spaces to ensure patient safety.

- Ensure Compliance. Receive actionable insights on best practices and compliance to stay updated with the most current updates to USP <797> & <800>.